Engineered Conveying Solutions

Jonson’s Engineering Services Division uses proven engineering, design and technology to provide our customers with the best engineered solution to their conveyor material handling applications.

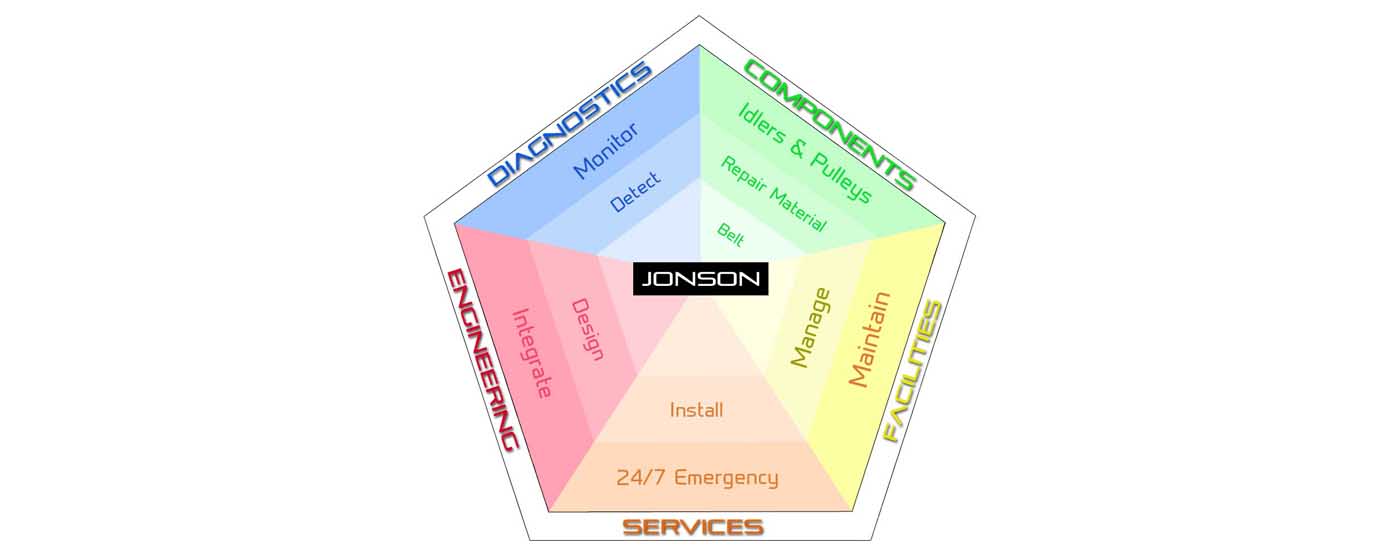

JONSON is now present to our customers as integrated offerings from One Source, including conveyor belt for all above and below ground systems, idlers and structure, system design, installation, aftermarket components and ongoing service. While all of these resources are available as a One Team approach, we do maintain stand-alone businesses with products, services, and personnel who concentrate their experience within one specialty.

While we believe that every company must grow in order to remain successful, nevertheless: We remain equally focused on value creation. Therefore, we will continue our search for strategic alliances, which further strengthen our values offering to performance-driven customers, while growing our business locally and worldwide.

Capabilities

New product development

Existing Products modifications

Onsite installations

Our customer's productivity

Optimizing conveyor belt life and components

Our years of practical bulk material handling knowledge and engineering capabilities not only improve our customers productivity and efficiency, but also reduces the power consumption factor, longevity of the belt thus leading to better downtime.

We can provide

Site surveys and inspections

Field measurements for chute design

Specification design

Redesign of existing equipment

Design review/recommendation

Certified CAD engineering drawings

Component specifications

State of the art fabrication capabilities

Oversee installations

Start-up & maintenance services

SUPPORT IN TOTAL COST OF OWNERSHIP

JONSON supports while investigating costs for any company utilizing conveyor systems, there is more to include than just equipment and labour required to build, maintain and operate the systems. Conveyor downtime will directly impact production leading to lower revenues and profitability. Conveyor systems are typically the life-line of the operation and their costs, though relatively low compared to the total mining operation, can have a disproportionate impact on the success of the overall operation.

MAXIMUM CONVEYOR AVAILABILITY

JONSON turnkey conveyor solutions can include one or all of the following: design, manufacturing, installation, maintenance, monitoring and refurbishment /replacement. The focus is on maximizing the conveyor availability in the safest and most cost effective way.