close

close

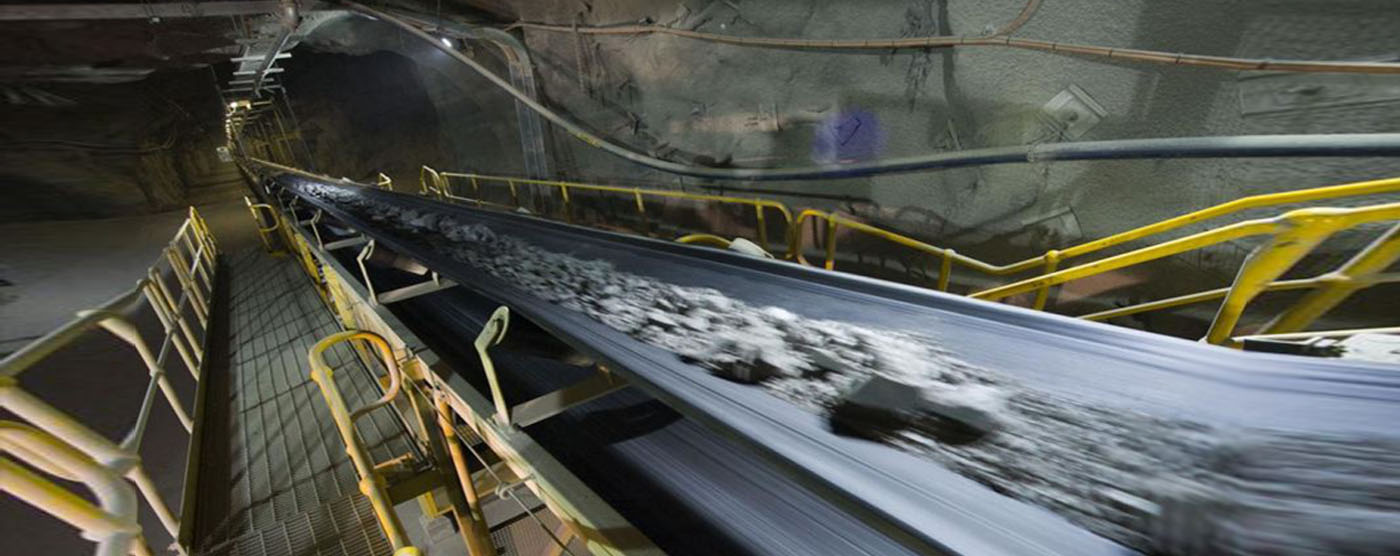

PVC / PVG Conveyor Belts

Range of Products

Jonson Fire Resistant belting has a proven track record of superior service in coal mining and other similar applications where the high, continuous output depends largely on the performance and reliability of the belt. Jonson Fire Resistant, designed primarily for use in underground and other potentially hazardous situations, meets and in many cases, exceeds the fire-resistance and anti-static requirements of all worldwide safety standards. Through its PVC compounds, customizable cover thickness and its solid woven carcass, making the belt ideal for conveying coal, potash, phosphate, fertilizer, clay, gypsum and salt. It is also suited for use in the timber industry.

PVC Table

| Belt Designation | Warp breaking Strength | Warp breaking Strength | Cover Thickness | Belt Thickness* | Belt Weight* | Minimum Recommended Drum Diameters | |

| lbs/in | kn/Mtr | v/Mtr | mm | mm | kg/sq.m | high tension(mm) | low tension(mm) |

| 2500 | 438 | 265 | 1.0×1.0 | 7.5 | 9.5 | 315 | 250 |

| 3500 | 610 | 265 | 1.0×1.0 | 8.0 | 10.5 | 400 | 315 |

| 4000 | 700 | 265 | 1.0×1.0 | 8.3 | 10.9 | 400 | 355 |

| 4500 | 788 | 352 | 1.0×1.0 | 8.5 | 11.2 | 500 | 355 |

| 5000 | 875 | 352 | 1.0×1.0 | 8.9 | 11.5 | 500 | 355 |

| 6000 | 1050 | 352 | 1.0×1.0 | 9.4 | 12.0 | 630 | 400 |

| 6500 | 1140 | 352 | 1.0×1.0 | 9.5 | 12.5 | 630 | 400 |

| 7000 | 1225 | 352 | 1.0×1.0 | 10.5 | 14.0 | 750 | 450 |

| 8000 | 1400 | 425 | 1.0×1.0 | 11.0 | 15.0 | 750 | 450 |

| 9000 | 1576 | 425 | 1.0×1.0 | 12.0 | 15.5 | 800 | 600 |

| 10000 | 1751 | 455 | 1.0×1.0 | 13.0 | 16.5 | 800 | 600 |

| 11000 | 1926 | 455 | 1.0×1.0 | 13.5 | 17.0 | 1000 | 750 |

| 12000 | 2100 | 455 | 1.0×1.0 | 14.5 | 18.0 | 1000 | 750 |

| 14000 | 2452 | 455 | 1.0×1.0 | 15.5 | 19.0 | 1250 | 800 |

| 15000 | 2625 | 455 | 1.0×1.0 | 16.5 | 20.0 | 1250 | 800 |

PVG Table

| Class Rating | Min Tensile Strength N/mm (Warp) | Min Tensile Strength N/mm (Weft) | Carcass Thickness | Carcass Weight | Cover Grade Recommended Thickness mm (PVG) | Min Pulley Dia mm |

| 680 | 680 | 265 | 6.5 | 8.5 | 1.5 x 1.5 | 400 |

| 800 | 800 | 320 | 5.9 | 9 | 1.5 x 1.5 | 500 |

| 1000 | 1000 | 350 | 7.5 | 9.7 | 2.0 x 2.0 | 630 |

| 1250 | 1250 | 350 | 8.5 | 11 | 2.0 x 2.0 | 750 |

| 1400 | 1400 | 450 | 9 | 11.5 | 2.0 x 2.0 | 750 |

| 1600 | 1600 | 450 | 9.5 | 12.3 | 2.0 x 2.0 | 800 |

| 1800 | 1800 | 450 | 9.5 | 12.3 | 2.0 x 2.0 | 800 |

| 2000 | 2000 | 450 | 10.5 | 13.6 | 3.0 x 3.0 | 1000 |

| 2500 | 2500 | 420 | 12.5 | 14.5 | 3.0 x 3.0 | 1200 |

| 3100 | 3100 | 420 | 17 | 17 | 3.0 x 3.0 | 1500 |

Technical Information

The table shows nominal figures for minimum warp & weft breaking strengths, belt thickness & weight for a selection of belt types, based on 1mm x 1mm PVC covers on either side. For every additional 1mm PVC, add 1.25kg/sq.mtr for PVC covers. Nominal values with 1+1 PVC covers.

Product Quality

- All-synthetic high tenacity centre warp yarns, for strength and minimum elongation.

- All-synthetic pile warp yarns, to protect against impact damage, improve adhesion and give superb fastener bedding.

- Composite weft yarn, to give optimum transverse rigidity and superb fastener holding.

- Woven selvedge to reduce edge-ware and improve belt life.

- Complete vacuum impregnation and consolidation of PVC compound through solid woven fabric, to improve tear strength and to reduce ingress of moisture.

- Special PVC cover, to reduce abrasion and improve carrying capacity through the life of the belt.

Product Advantages

- Homogenous and integrated belt structure.

- High tear/rip resistance.

- High modulus belt, for low operating elongation.

- Vastly superior fastener holding.

- Optimum longitudinal flexibility, to allow use of lower pulley diameters.

- Woven selvedge, to reduce rate of edge wear.

- Trough ability, designed for belt to perfectly seat on the idlers.

Application of PVC/PVG

Widely used in fiery mines i.e. underground coal mines, power stations, chemical and metallurgy industries

Quality

- Properties : Excellent flame, Anti-static characteristics for fiery applications

- Strength : High tensile strength in proportion to weight

- Carcass : Good integrity, no delamination and excellent resistance to impact

The Advantages of JONSON PVC/PVG belts

Complete in-house manufacturing - from yarn preparation, fabric weaving, compound mixing to belt finishing - to ensure total process and quality control at each step of manufacturing activity. Each belting roll is tested for physical, fire retardant and anti static properties - one of the few manufacturers who can claim to do 100% tests on all belts. One of the best conveyor belting test facilities where a fully equipped test laboratory conducts test of all incoming yarns and chemicals, as well as on finished product, including tests for flame, static conductivity drum-friction, limited oxygen index, etc. In addition, physical tests like tensile strength, elongation, tear, adhesion, fastener holding, trough ability etc. are also conducted as routine tests.